Products

We offer a wide range of high-quality mechatronic components for advanced automation applications, supported by a strong network of trusted suppliers. Our product lineup includes high-performance DC, BLDC, frameless, and DC servo motors , as well as brakes, clutches, motor drivers, linear actuators, integrated robot drive systems, and slip rings. We are proud to partner with leading suppliers. These collaborations ensure that our products meet the highest standards of precision, reliability, and innovation, enabling us to provide tailored motion control solutions for cutting-edge robotics and automation projects.

Robot Drive Systems

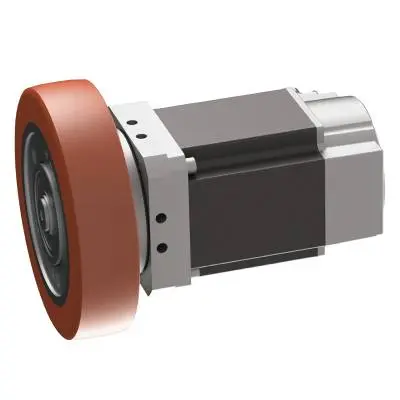

Nidec AGV Wheel motor

The LD AGV Wheel motor is designed to meet the demanding requirements of AGV applications. The direct mount design helps streamline installation, while the low profile gearbox provides gear reductions up to 9:1. Our system outputs up to 250Nm of torque, and speeds up to 450 rpm.

AGVs have various accuracy requirements, so we provide a selection of various feedback options that can tailor the system to your specific needs. Brakes are available upon request. This system can be designed around your power source - whether it is 48V or 400V, we have options available.

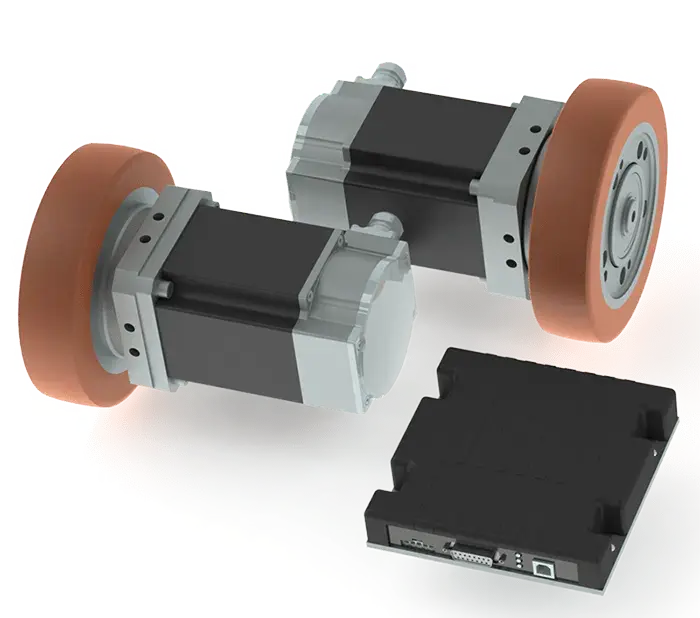

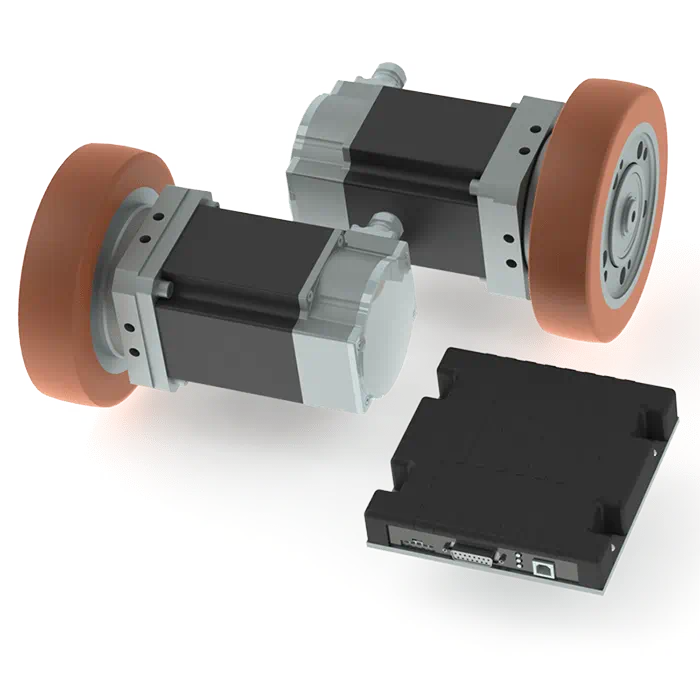

Nidec AGV kit

Building robots is faster and easier than ever before with Nidec Motion Control’s AGV Kits! Our kits include integrated Motor/Gearbox/Wheels with a matching, pre-configured and tuned motor controller to carry payloads of 500KG, 1000KG or 2000KG depending on the kit.

AGV’s need two motors to move and steer. Nidec Motion Control is able to make this work with a single controller versus two. Compared to the traditional One Motor/One Controller approach, the Dual Channel is simpler, cheaper, safer and easier to integrate and maintain. Two controllers can even team up to drive 4 motors to move Omnidirectional Robots.

Brakes & Clutches

Kern Motion Magnetic Particle Brake

As the name suggests, magnetic particle brakes use a specially developed magnetic powder to provide the braking torque. The magnetic particles align themselves with the magnetic field lines and ensure a force-fit connection between the rotor and housing. By varying the strength of the current, and therefore also of the magnetic field, these brakes can be precisely adjusted, making them suitable for a wide range of applications from 10 Nm - 100 Nm.

Infinitely variable torque

Torque virtually independent of speed

Low-wear and silent operation

Compact design

Kern Motion Permanent Magnet Brake

A hysteresis brake equipped with permanent magnets makes these brakes suitable for a wide range of applications from 0.15 Nm to 8 Nm, where a constant torque is required and no voltage source is available. The robust aluminium housing allows the brake to dissipate heat effectively to the surroundings, making it suitable for higher slip powers.

Compact and robust design

Speed-independent torque delivery

Completely wear and maintenance-free

No voltage source required

Suitable for higher slip powers

Can be used both as a brake and as a clutch

Kern Motion PMK Hysteresis Brake

The PMK is one of our smallest adjustable hysteresis brakes. Thanks to the use of high-energy neodymium magnets, these brakes do not require any electricity for operation. Thanks to the special design, the brake can be mechanically adjusted in 10 increments from 0.008 Nm to 0.05 Nm, allowing the torque to be precisely adapted to the relevant application. This makes this brake very attractive, especially for small applications.

Compact and robust design

Speed-independent torque delivery

Completely wear and maintenance-free

No voltage source required

Manually adjustable (10 levels)

Can be used both as a brake and as a clutch

Kern Motion Hysteresis Brake

The PMB series consists of adjustable hysteresis brakes with permanent magnets. A ring on the outer diameter allows our brake to be set precisely to the required torque. The braking torque ranges from virtually 0 Nm to over 2 Nm. This brake is therefore suitable for a variety of applications, especially ones in which the required torque cannot be precisely determined. In this case, the output is configured directly in the application.

Compact and sleek design

Speed-independent torque delivery

Linear torque increase

Completely wear and maintenance-free

No voltage source required

Manually adjustable (adjustment ring on the outer diameter)

Can be used both as a brake and as a clutch

We are here to help!

With such a wide range of motion control options available it can be overwhelming. We would be happy to do the hard work for you, so please feel free to contact us with your requirements!